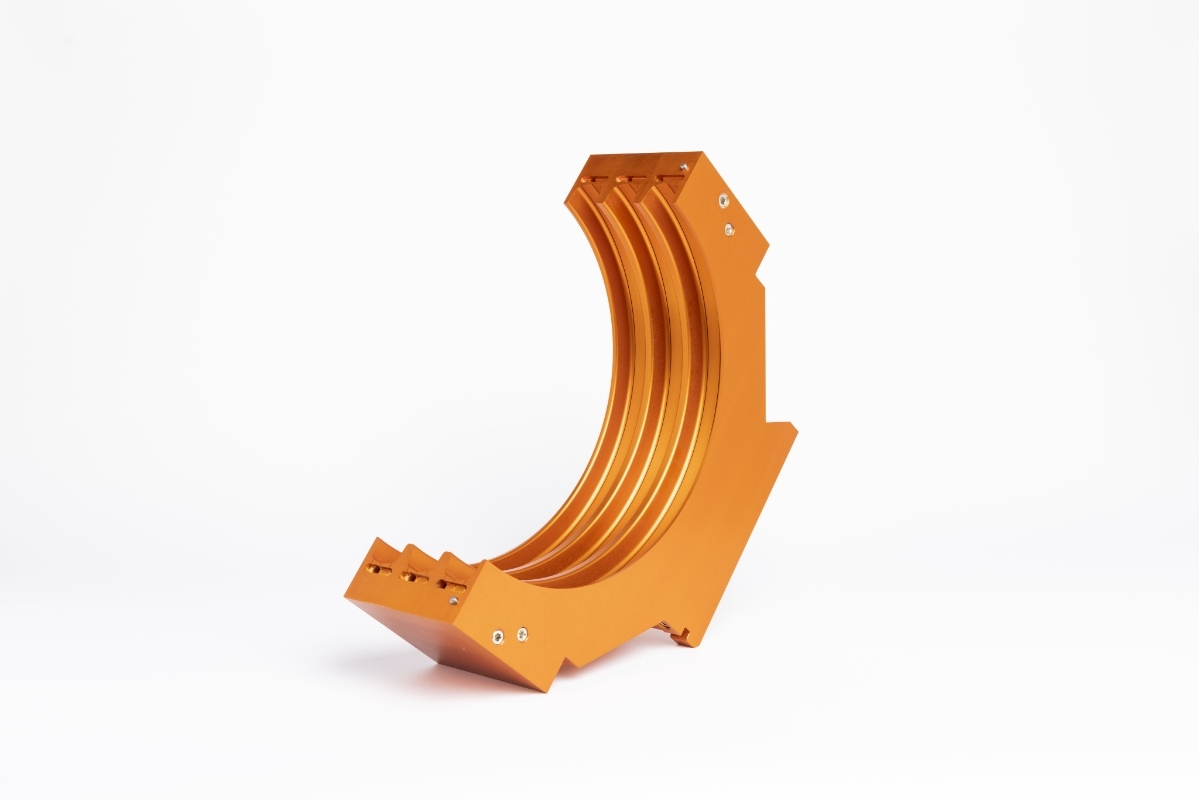

The upper range of water-cooled corrugators of ITIB Machinery is characterised by aluminium moulds. They are in pairs, machined on five axis CNC machines to get extremely low tolerance and high-quality pipes.

Aluminium is used for a better heat transfer and lower weight. Their surface is hard anodized and they are fixed to hardened steel holders, running without any link inside hardened channels.

The fixing system consists of a single bolt for fast changeover.

The cooling water flows directly inside the moulds maximizing the cooling effect for best performance (direct cooling).

Inside the mould the vacuum forming circuit is machined as well. In fact, vacuum forming is standard on these models.

While FV200 is a no compromise corrugator, designed for maximum cooling and speed, FV250 and FV400 corrugators allow to use double or triple cavity moulds. This solution reduces the number of set of moulds for a lower investment and an even faster changeover time, without effecting to much the output.