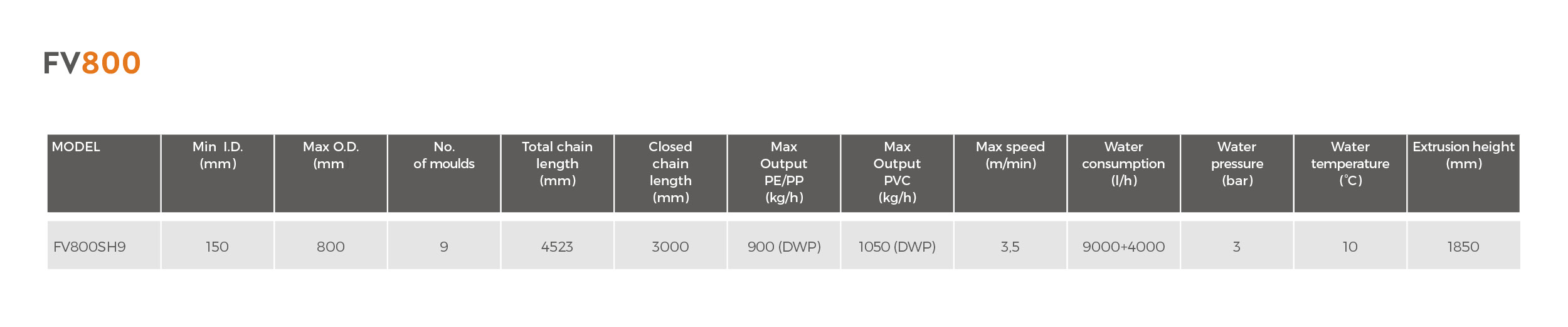

It has its main application in the production of double-wall underground drainage and sewage pipes for infrastructure.

It replaces the FV700 model, adding to the pipes range the strategic 800mm size.

The main features of FV800 are:

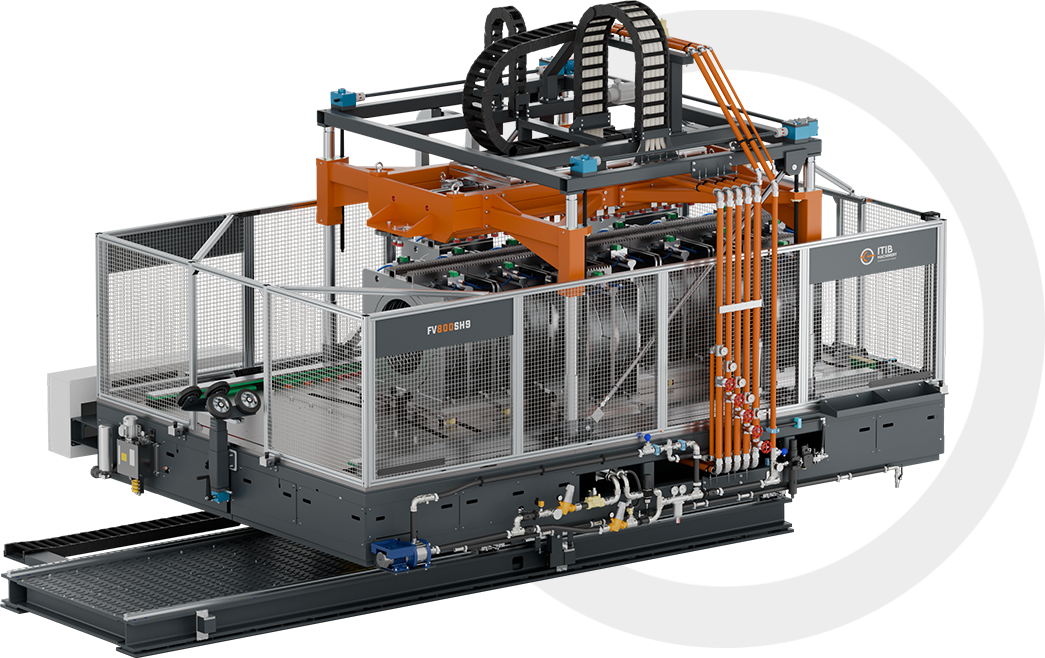

- Shuttle system for moulds movement

- Maximum mechanical speed up to 3,5m/min

- Optimized cooling channel length for best performance

- Direct cooling with water flowing inside the moulds

- Aluminium moulds for high heat transfer

- Wide range of pipes from 150mm I.D. up to 800mm O.D.

- Moulds fixed to hardened steel supports

- Mould fixed to holder with two bolts for fast changeover

- Single drive for both left/right chains for perfect moulds alignment

- Vacuum forming system as a standard with variable speed pump for energy saving

- Automatic oil/grease lubrication with timer

- Corrugator sliding on rails for easy access to die-set during start-up

- Electrical up/down, left/right sides adjustment for perfect centring

- Emergency push back electrical motor with ball bearing screw

- UPS unit to face power failure and allow movement of key parts

- User friendly interface for parameters setting and production control

- Position auto setting of upper vacuum bar based on moulds size

- Moulds temperature setting and control is available as an option

- Corrugator position control device is available as an option

- Safety protections for safe corrugator handling

- Prepared for mould parking station for in-line coupling

- Industry 4.0 ready

Other PRODUCTS

FOR MORE INFORMATION CONTACT US.