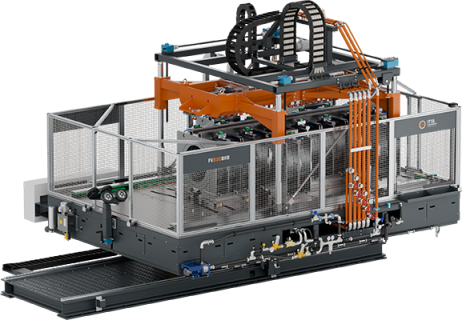

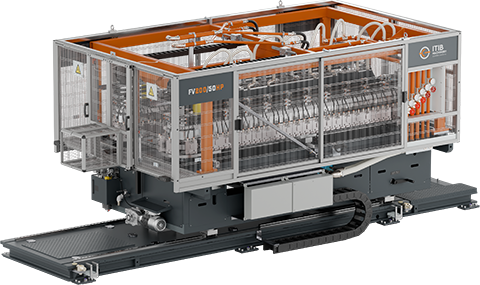

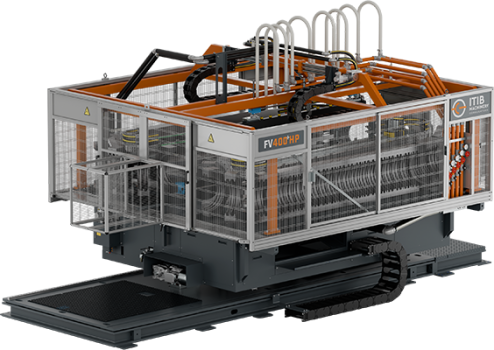

The company’s core business is the production of corrugators, all water-cooled.

Depending on the size, shape and application of the pipe to be extruded, the machines can provide two different forming systems:

– forming system using low-pressure air that is introduced through the extrusion head, pushing the plastic material towards the moulds by blowing

– vacuum forming system, whereby the plastic material is sucked towards the corrugation by the vacuum applied through special channels machined in the moulds and guides in which they slide

ITIB Machinery International wide range of corrugators allows the production of both single-wall PE, PP, PVC, PA, EVA, PVDF and double and triple-wall PE, PP, PVC pipes from an inner diameter of 4.5mm up to an outer diameter of 800mm.

Smaller models use nitrided steel moulds, equipped with an upper rack and driven by a gear inside cooled guides; medium and large models use aluminium moulds fixed to steel holders with a chilled water-cooling system flowing directly into them, in combination with the vacuum forming system.

These technical solutions allow increased productivity and are accompanied by special features designed to optimise changeover time, minimise maintenance, and facilitate machine operation by means of a simple and intuitive operator interface. There is the possibility of integrating the production line within the company through Industry 4.0 data exchange and machine supervision via remote assistance.

FOR MORE INFORMATION CONTACT US.